Technological difficulties and solutions in titanium alloy forging processing

Titanium alloys are widely used in various fields such as aerospace, medical, chemical, etc. due to their high strength, low density, excellent corrosion resistance, and good biocompatibility. However, forging titanium alloys is a technically challenging process that involves many challenges. This article will explore in detail the main difficulties and solutions in titanium alloy forging processing.

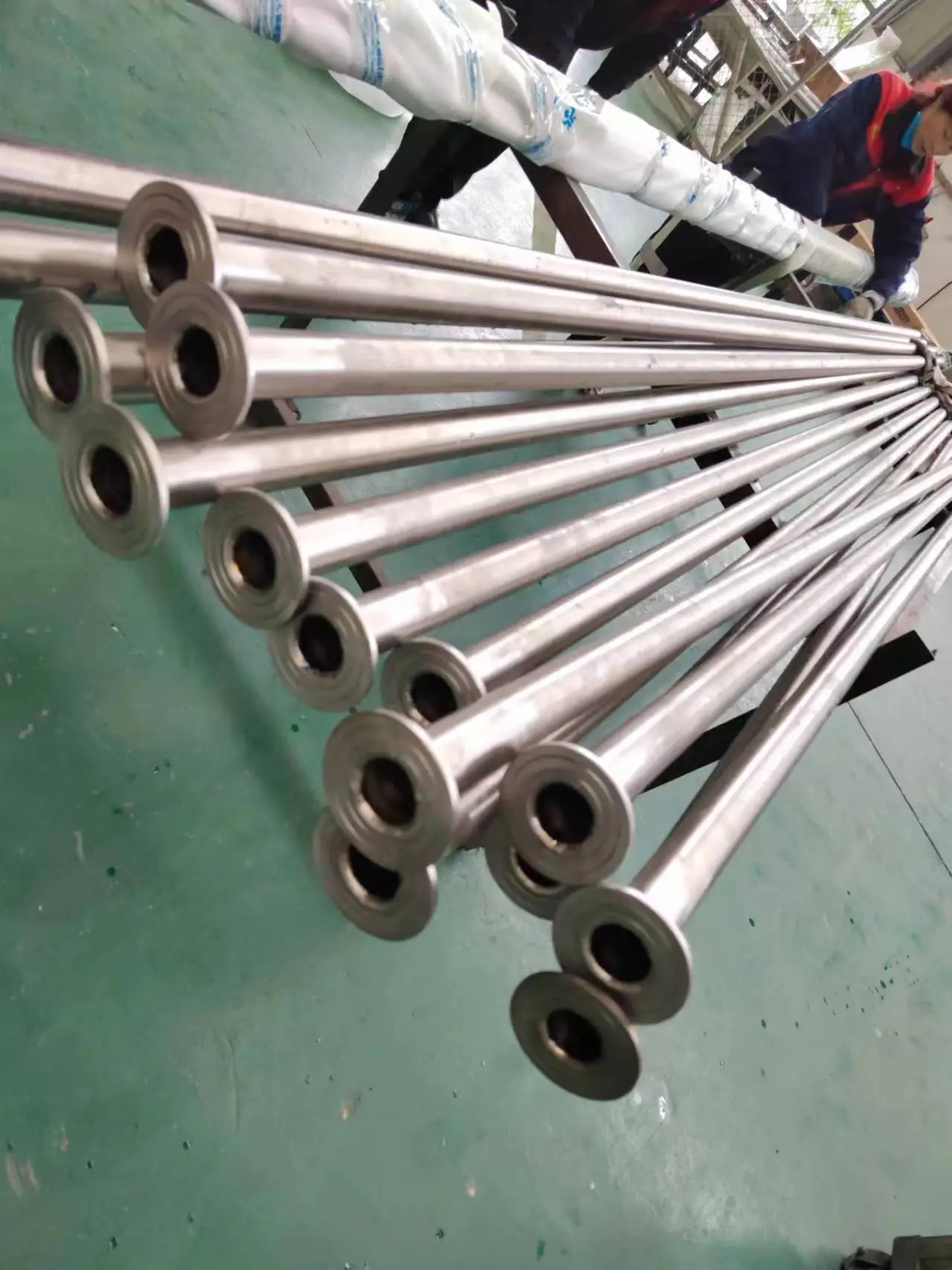

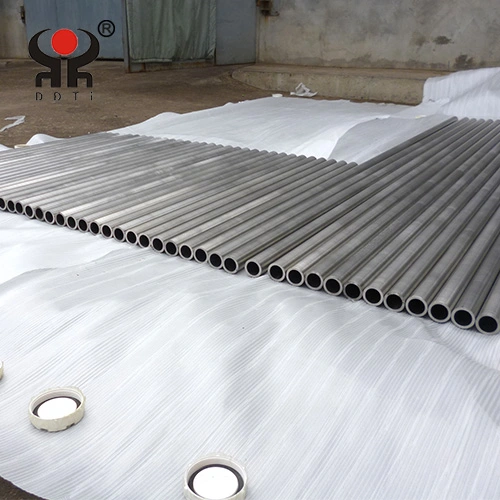

Excellent application of titanium coil in the refrigeration industry

Titanium coil, a refrigeration component mainly made of titanium metal, plays a crucial role in the refrigeration industry. Its unique physical and chemical properties not only endow titanium coils with excellent corrosion resistance and high strength, but also make them an indispensable key element in refrigeration systems.

Preparation of Analysis Report on Market and Investment Prospects of Medical Titanium Alloy Rod Materials

With the continuous advancement of global medical technology, medical titanium alloys, as a metal material with excellent biocompatibility and mechanical properties, are increasingly widely used in fields such as implantable medical devices and artificial joints. This report aims to provide a comprehensive and in-depth analysis of the market status, development trends, and investment prospects of medical titanium alloy bars.

Innovative application of titanium alloy in oil well pipes under extreme geological conditions

With the continuous development of oil resources in China, the mining output of oil wells under conventional geological conditions has shown an obvious downward trend. Faced with this severe situation, the focus of oil extraction has to shift to more complex and challenging special geological environments. These oil fields in special geological environments often have harsh characteristics such as ultra deep (such as the oil and gas wells in Tarim Oilfield, Xinjiang, which are generally over 4000 meters deep), high temperature, high pressure, and rich in hydrogen sulfide, bringing unprecedented difficulties to oil extraction.

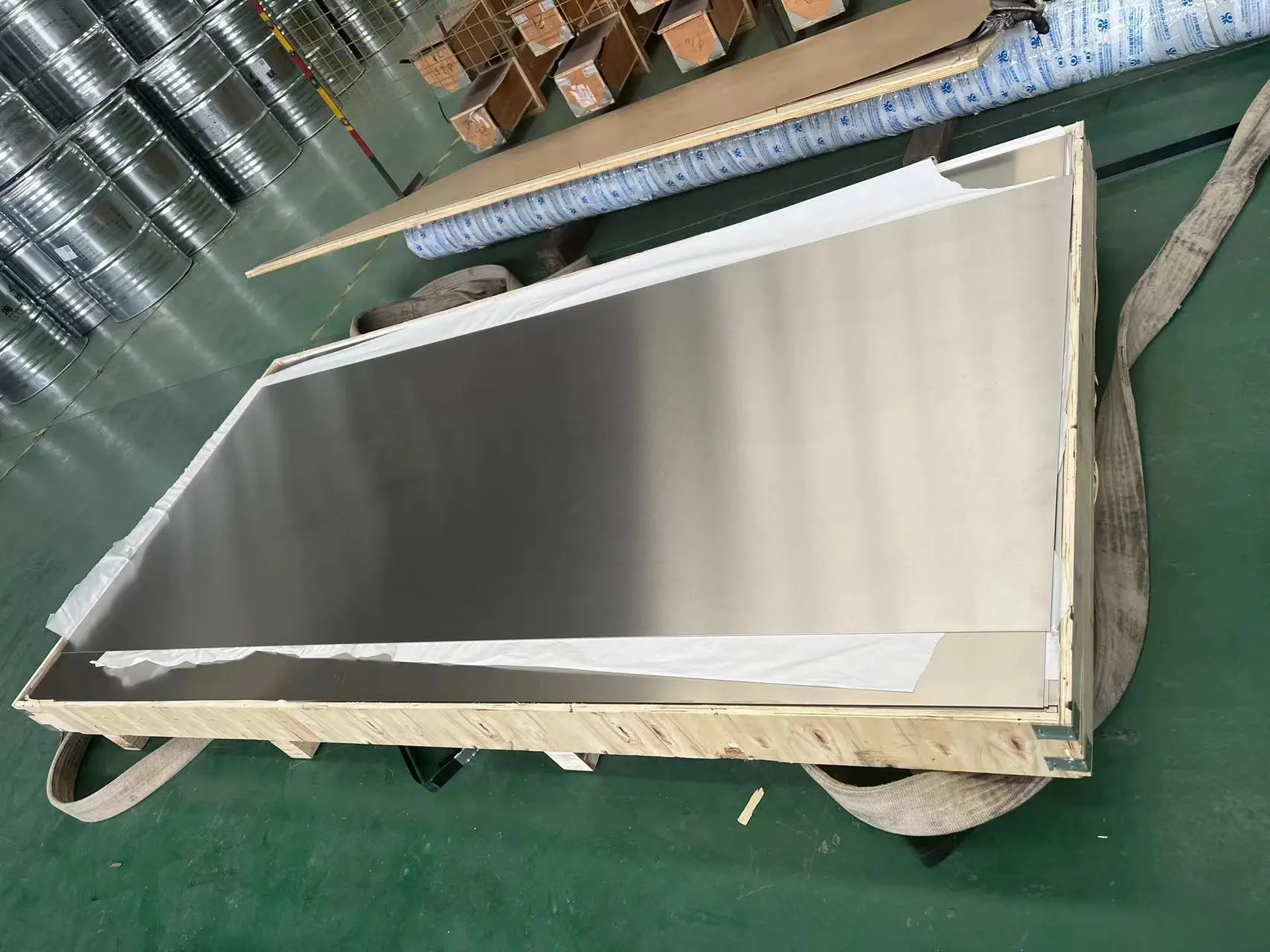

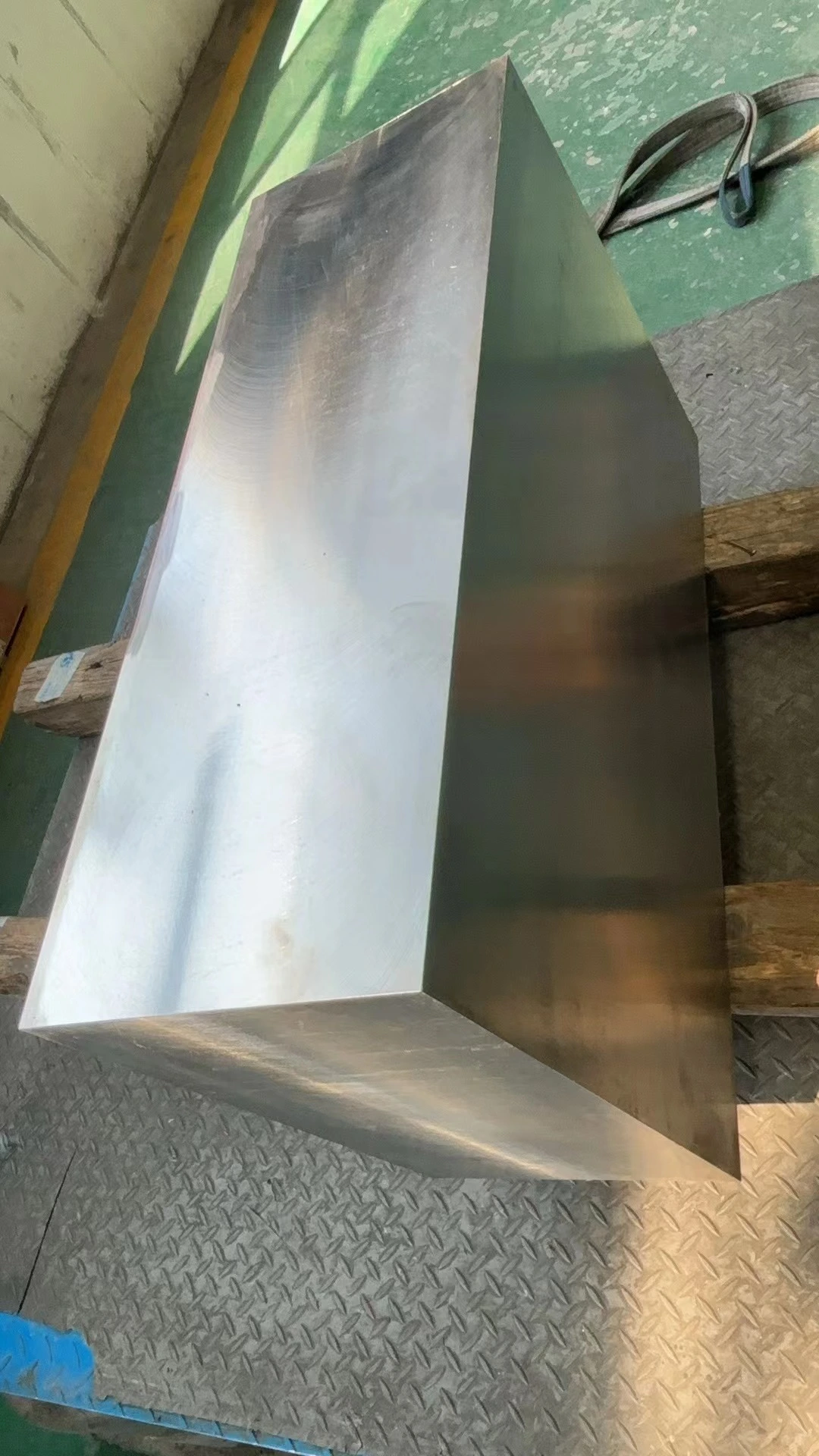

Detailed explanation of titanium plate production process: the entire process from hot rolling to cold rolling and finishing

Analysis of Key Technologies for Precision Grinding and Polishing of Titanium Alloys

Titanium and its alloys, as important biomedical materials, have shown significant advantages in the field of oral restoration, but their special physical and chemical properties impose strict requirements on processing technology. This article systematically summarizes the key points and application characteristics of three mainstream surface treatment technologies for the processing difficulties of titanium materials.

Key points and quality control of titanium alloy forging process

This process can increase the equiaxed rate of titanium alloy as cast microstructure to over 90% by precisely controlling thermodynamic parameters and deformation paths, effectively avoiding the occurrence of macroscopic defects and meeting the technical requirements of aviation grade forgings. In actual production, dynamic process optimization needs to be carried out based on the phase transition kinetics of materials.

The fixing method and selection of titanium coil

Analysis of Flaw Detection Defects and Optimization of Precision Forging Process for Titanium Rings and Titanium Alloy Forgings

Precision forging technology has become the preferred solution for titanium rod production due to its high efficiency and precision, but it needs to be continuously optimized through defect analysis. By dynamically monitoring the forging temperature, stress field distribution, and material flow behavior, the defect rate can be further reduced and the comprehensive performance of titanium alloy forgings can be improved.