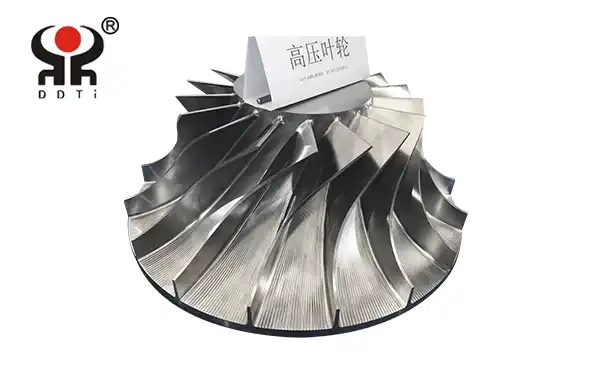

Technological difficulties and solutions in titanium alloy forging processing

2025-02-26 17:10:43

1. Low thermal conductivity

The thermal conductivity of titanium alloy is relatively low, only 1/7 of steel, 1/16 of aluminum, and 1/25 of copper. This means that during the forging process, heat is difficult to transfer quickly, leading to rapid accumulation of heat in the cutting area, causing the tool and mold to withstand extremely high temperatures, accelerating wear and even failure. In addition, high temperature can also damage the surface integrity of titanium alloy parts, leading to a decrease in geometric accuracy, and in severe cases, work hardening may occur, damaging their fatigue strength.

Solution:

Use high-performance tool materials such as hard alloys, ceramics, etc. to improve the high temperature resistance and wear resistance of the tool.

Use coolant for sufficient cooling to reduce the temperature of the cutting area and minimize heat accumulation.

Optimize forging process parameters, such as reducing cutting speed, increasing feed rate, etc., to reduce tool wear and improve machining efficiency.

2. Low elastic modulus

The elastic modulus of titanium alloy is relatively low, and it is prone to elastic deformation during forging, especially when processing thin-walled or ring-shaped parts, which is a more prominent problem. Due to the strong plastic deformation ability of titanium alloys, local deformation may exceed the elastic range when the workpiece material is subjected to external forces, resulting in plastic deformation. This plastic deformation not only increases cutting pressure and intensifies the phenomenon of "elastic" rebound of the workpiece, but also further increases the friction between the tool and the workpiece, leading to a decrease in cutting efficiency and tool life.

Solution: Adopting new processing methods such as ultrasonic machining technology to reduce the contact time between the tool and the workpiece and extend the tool's service life.

Optimize forging process parameters, such as reducing cutting speed, increasing feed rate, etc., to reduce tool wear and improve machining efficiency.

3. Adhesion and high vibration characteristics

Titanium alloy has a strong affinity for cutting tools and is prone to adhere to them during the cutting process, forming continuous chips that interfere with the cutting process and may even cause tool damage in severe cases. In addition, the high vibration characteristics during the processing of titanium alloys are also a major unstable factor, which not only exacerbates tool wear, but also seriously affects machining accuracy and surface quality.

Solution:

Use high-performance tool materials such as hard alloys, ceramics, etc. to improve the high temperature resistance and wear resistance of the tool.

Adopting new processing methods such as ultrasonic machining technology to reduce the contact time between cutting tools and workpieces and extend the service life of cutting tools.

4. Detail issues

Attention should also be paid to some details during the forging process of titanium alloy. For example, before forging, the chemical composition and microstructure of titanium alloy raw materials should be strictly controlled to avoid defects such as inclusions and pores; During the forging process, the heating temperature and holding time should be strictly controlled to avoid overheating or overburning; After forging, timely heat treatment should be carried out to eliminate residual stress and improve the mechanical properties of the material.

Solution: Strictly control the chemical composition and microstructure of titanium alloy raw materials.

Strictly control the heating temperature and holding time to avoid overheating or overburning.

Timely heat treatment should be carried out after forging to eliminate residual stress and improve the mechanical properties of the material.

Titanium alloy forging is a technically challenging process that involves multiple difficulties such as low thermal conductivity, low elastic modulus, adhesion, and high vibration characteristics. In order to overcome these difficulties, the industry has explored a series of effective solutions and technical means. By using high-performance tool materials, optimizing forging process parameters, using coolant and new machining methods, and strictly controlling details during the forging process, the efficiency and quality of titanium alloy forging can be effectively improved.

Baoji Dingding Titanium Products Co., Ltd. is committed to producing high-quality medical titanium alloy materials. Welcome to inquire: 3412107@bjddt.com