Detailed explanation of titanium plate production process: the entire process from hot rolling to cold rolling and finishing

2025-03-13 16:23:03

1、 The production process of hot-rolled titanium plate mainly uses continuous casting slab or initial rolling slab as raw materials. After being heated by a step heating furnace, these raw materials are subjected to a high-pressure water descaling device to remove surface oxide scale, and then enter the roughing mill for preliminary rolling. After rough rolling, the material head and tail are cut off and then enter the precision rolling mill for computer-controlled rolling. After final rolling, the titanium plate is cooled by a laminar cooling device and coiled into straight coils by a coiling machine.

The head and tail of straight curls often appear tongue shaped and fish tail shaped, with relatively poor accuracy in thickness and width. The edges often have defects such as wavy, folded, and tower shaped shapes. In addition, the roll weight of straight hair rolls is relatively heavy, and the inner diameter of titanium tubes is usually 760mm, which is suitable for use in the pipe making industry.

In order to obtain higher quality hot-rolled titanium plates, straight coils need to go through finishing lines such as cutting heads, tails, edges, and multiple passes of straightening and flattening. The processed titanium plate can be further cut or rewound into products such as hot-rolled titanium plate, flat hot-rolled titanium tube, longitudinal cutting strip, etc. If the hot-rolled finished coil is acid washed to remove the oxide skin and coated with oil, it can become hot-rolled acid washed plate coil.

2、 Production process of cold-rolled titanium plate

Cold rolled titanium plates are made from hot-rolled titanium tubes, and after acid washing to remove oxide scales, they are subjected to cold rolling. The cold-rolled product is a rolled hard coil. Due to continuous cold deformation causing cold work hardening, the strength and hardness of the rolled hard coil increase, while the toughness and plasticity index decrease. Therefore, the stamping performance deteriorates and can only be used for parts with simple deformation.

Rolled hard coils can be used as raw materials for hot-dip galvanizing plants, as hot-dip galvanizing units are usually equipped with annealing wires. The coil weight of cold-rolled titanium plate is generally between 6-13.5 tons, and the inner diameter of the titanium tube is 610mm. In order to improve the performance of cold-rolled titanium plates, continuous annealing (CAPL unit) or hood furnace annealing treatment is usually required to eliminate cold work hardening and rolling stress, and achieve the corresponding mechanical performance indicators specified in the specifications.

The surface quality, appearance, and dimensional accuracy of cold-rolled titanium plates are superior to hot-rolled plates, and their thickness can be rolled to around 0.18mm, making them highly favored by users. By using cold-rolled titanium tubes as substrates for deep processing, high value-added products can be produced, such as electroplated zinc, hot-dip galvanized, fingerprint resistant electroplated zinc, color coated titanium coils and vibration reducing composite titanium plates, PVC laminated titanium plates, etc. These products have excellent qualities such as beauty and high corrosion resistance, and have been widely used.

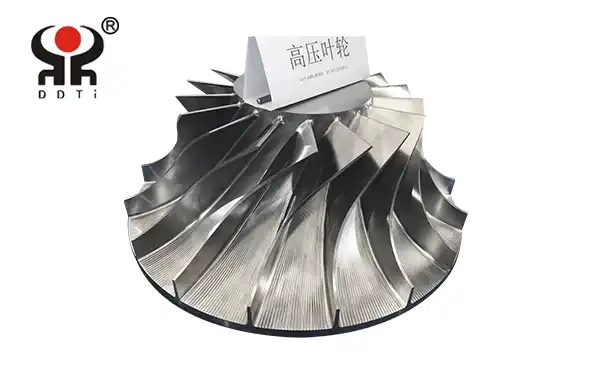

3、 Precision processing

After annealing, cold-rolled titanium pipes need to undergo finishing treatment, including cutting heads, tails, edges, leveling, flattening, rewinding, or longitudinal shearing plates. These treatments can further improve the dimensional accuracy and surface quality of titanium plates, meeting the different needs of users.

4、 Application Fields

Hot rolled and cold-rolled titanium plates are widely used in industries such as automobile manufacturing, household appliances, instrument switches, construction, and work furniture. The weight of each bundle of titanium plates after bundling is 3-5 tons, and the weight of flat rolls is usually 3-10 tons per roll.

In summary, the production process of titanium plates includes multiple stages such as hot rolling, cold rolling, and subsequent finishing treatment. Each stage has its specific process requirements and quality control standards to ensure that the quality and performance of the final product meet user needs.

Baoji Dingding Titanium Products Co., Ltd. is committed to producing high-quality titanium and titanium alloy materials. Welcome to inquire: 3412107@bjddt.com