Titanium alloys: Key materials for future energy technologies

Study on the influence mechanism of different annealing structures on dynamic impact properties of TC4 titanium alloy

In the arena of materials science, TC4 titanium alloy is like an all-round champion, dominating high-end fields such as aerospace and medical devices with its outstanding performance of high strength and low density. When this "metal warrior" encounters the harsh test of high-speed impact, its internal microstructure becomes the key armor that determines the outcome. This article will deeply analyze how different annealing processes forge the microscopic "armor" of TC4 titanium alloy and reveal the mystery of its regulation of dynamic impact performance.

TA1 titanium alloy: Decoding the high temperature strength limit and oxidation protection mechanism of industrial pure titanium

This study provides theoretical support for the design of a new generation of heat-resistant structural materials by revealing the essential mechanism of the high-temperature performance of TA1 titanium alloy. With the development of extreme manufacturing technologies, the application prospects of this material in fields such as the thermal protection system of supersonic aircraft and the cladding materials of fourth-generation nuclear reactors are worth looking forward to.

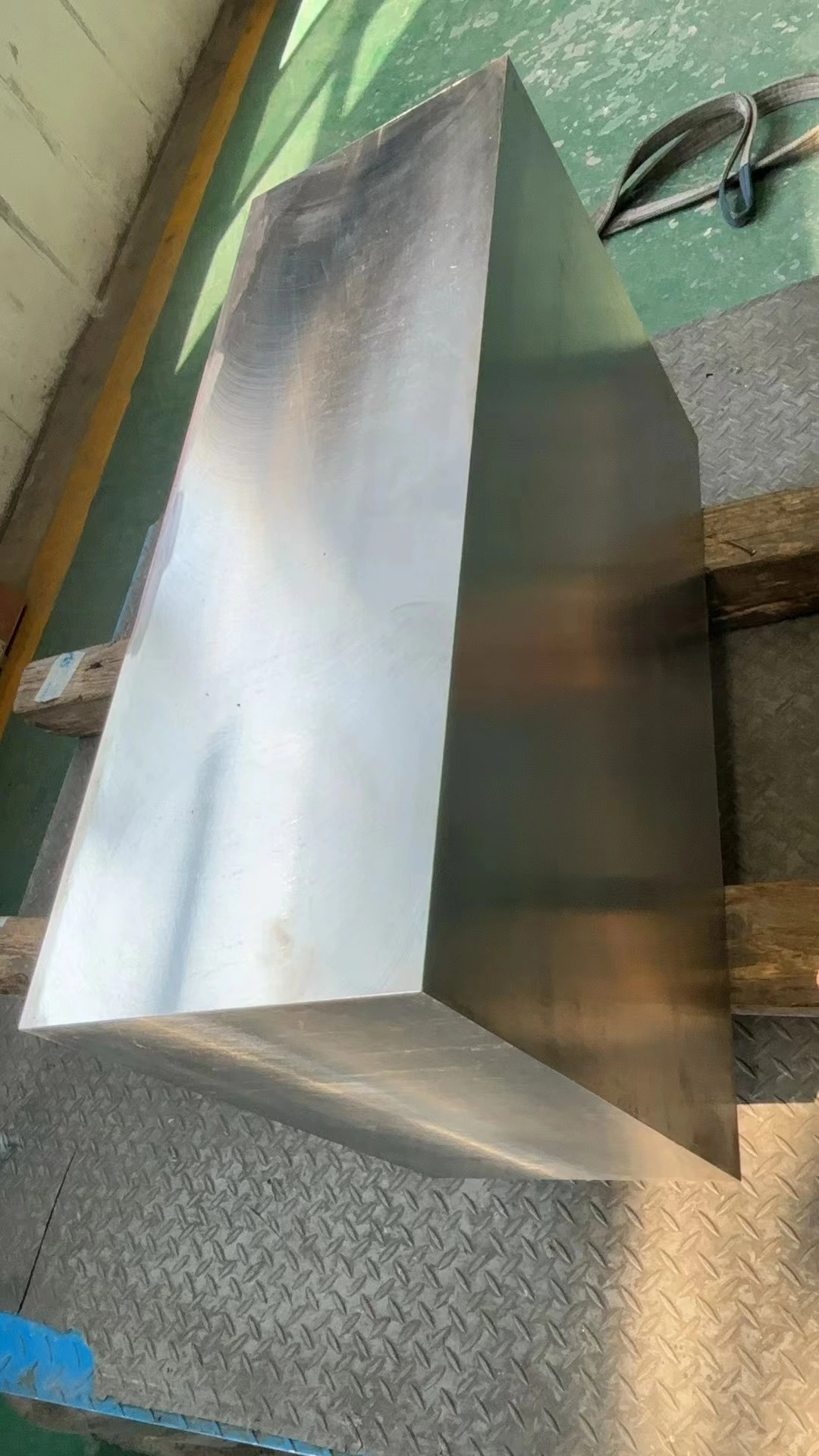

Precision manufacturing: A Comprehensive process Analysis of Titanium Alloy Tubes from smelting to Forging

Titanium alloy tubes, as star products in the field of high-end industrial materials, occupy an important position in cutting-edge fields such as aerospace, Marine engineering, and biomedicine due to their high specific strength, strong corrosion resistance, and excellent thermal stability. Its unique material advantages are not only reflected in the mechanical properties of tensile strength reaching over 900MPa, but also in the biocompatibility that perfectly matches human bones. These characteristics make the processing technology of titanium alloy tubes a technological high ground in modern manufacturing.

Analysis of TA8 Titanium Alloy Capillary Heat Treatment Process Optimization and Multi-Scenario Application Technology

Research on the Mechanism and Process Optimization of Titanium Alloy Cutting Processing

The processing of titanium alloys requires the establishment of a collaborative system for thermal management, parameter optimization and tool innovation. By using YG type cemented carbide tools in combination with a linear speed of 30-50m/min and 7MPa high-pressure cooling and other process combinations, the processing efficiency can be increased by more than 40%. With the maturation of micro-lubrication (MQL) and adaptive machining technologies, titanium alloy processing is breaking through towards low damage and high precision, providing a new technical path for the manufacturing of precision components in aerospace.

Baoji Dingding Titanium Products Co., Ltd.: An Innovative Leader in Medical Titanium Materials

With the rapid advancement of medical technology, titanium has emerged as a core material in high-end medical fields such as orthopedics, dentistry, and cardiovascular applications, thanks to its exceptional biocompatibility, lightweight nature, high strength, and corrosion resistance. Baoji Dingding Titanium Products Co., Ltd., as a leading supplier of medical-grade titanium materials in China, remains committed to innovation and quality, providing safe and reliable titanium solutions for the global healthcare industry.