Precision manufacturing: A Comprehensive process Analysis of Titanium Alloy Tubes from smelting to Forging

2025-04-24 15:49:14

I. Precision Smelting: Genetic Coding of Material Properties

1. Raw material purification process

By adopting the dual process of plasma cold bed melting (PAM) and electron beam melting (EBM), and through high-temperature refining above 3000℃, the purity of sponge titanium and alloying elements such as Al and V is increased to the level of 99.995%. The depth of the molten pool is precisely controlled within the range of 500 to 800mm to ensure the full volatilization of impurity elements.

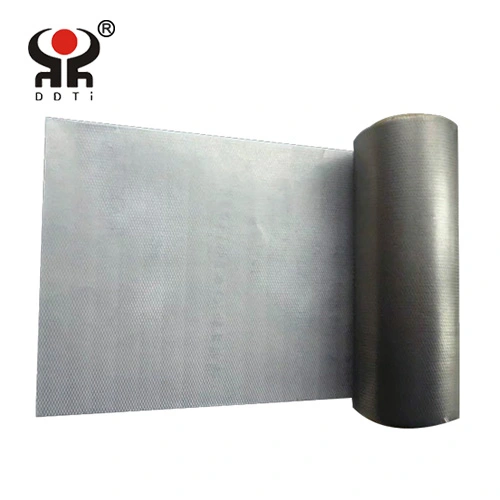

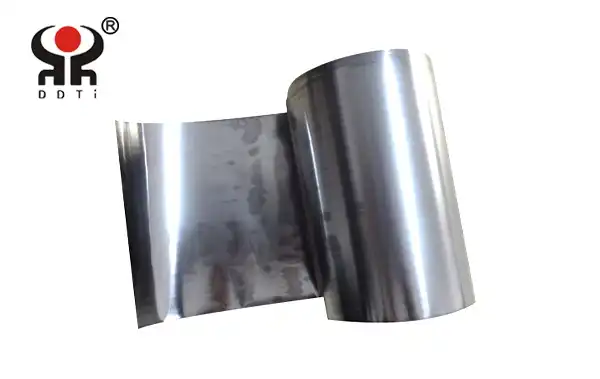

2. Tube billet forming technology

Direct casting method: Tubular ingots with diameters of Φ300×6000mm are prepared through centrifugal casting process, and the wall thickness tolerance is controlled within ±1.5mm

Drilling processing method: Deep hole drilling is carried out on solid ingots with a diameter of Φ500mm. The gun drilling process is adopted to achieve deep hole processing with an L/D ratio of 30:1, and the processing accuracy reaches H7 grade

Ii. Intelligent Forging: Directional Regulation of Microstructure

Multi-directional die forging process

Three-way forging is carried out within the temperature window of 20-50℃ below the β -phase transition point (the specific temperature is adjusted according to the alloy grade) using a 20,000-ton fast forging machine. The deformation of each pass is strictly controlled within the range of 30%-50%, and the metal streamline distribution is simulated in real time through the DEFORM software.

2. Radial forging finishing

The four-hammerhead radial forging machine forges at a frequency of 120 times per minute

The mandrel adopts gradient cooling technology, and the surface hardness is maintained at 62-65HRC

The thinning rate of wall thickness in each pass is 8%-12%, and the deviation of the final forging temperature is ≤±15℃

Iii. Process Control: Digital Practices for Quality Assurance

1. Online detection system

A composite detection unit integrating a laser diameter gauge (with an accuracy of 0.01mm), an infrared thermal imager (±2℃), and an ultrasonic flaw detector (with a sensitivity of Φ0.8mm) achieves 100% online full inspection.

2. Organizational optimization strategy

The optimal heat treatment system was determined through Thermo-Calc thermodynamic calculation. The double annealing process was adopted: the first was 850 ° C ×2h/AC, and the second was 600 ° C ×4h/AC, to stabilize the grain size at ASTM grade 8-10.

This manufacturing system, which integrates advanced technologies such as material computing, intelligent equipment, and digital twins, not only increases the yield of titanium alloy tubes to over 85%, but also extends the fatigue life of the products by 3 to 5 times compared to traditional processes. With the introduction of additive manufacturing technologies such as 3D printing, titanium alloy tubes are continuously evolving towards innovative directions such as topologically optimized structures and gradient functional materials.

Baoji Dingding Titanium Products Co., Ltd. is dedicated to manufacturing high-quality titanium alloy products. Welcome to inquire: 3412107@bjddt.com.