A、 Introduction to TA1 Titanium Alloy Material

TA1 titanium alloy, as a pure titanium material, is classified as an alpha type titanium alloy. It stands out among many high-performance materials due to its excellent corrosion resistance, high strength, and excellent processing performance. The main chemical component of TA1 titanium alloy is titanium (Ti), with a content of not less than 99.5%. At the same time, the material has extremely low oxygen, hydrogen, nitrogen, and carbon impurity content, which together ensure its excellent comprehensive performance. Therefore, TA1 titanium alloy is widely used in high-end industries such as aerospace, chemical, and medical devices, becoming an indispensable key material in these fields.

B、 Performance characteristics of TA1 titanium alloy

1. Density and strength: The density of TA1 titanium alloy is 4.51g/cm ³, which is about 60% of that of steel, making it significantly advantageous in areas with high lightweight requirements. Despite its low density, the strength of TA1 titanium alloy is comparable to some alloy steels, with a tensile strength of about 345MPa, a yield strength of 205MPa, and an elongation rate of up to 20% -30%, demonstrating good plasticity and toughness.

2. Corrosion resistance: TA1 titanium alloy exhibits strong corrosion resistance in various corrosive media. Especially in harsh environments such as seawater, chloride, and sulfuric acid, its corrosion resistance is far superior to stainless steel and other traditional materials. This characteristic makes TA1 titanium alloy particularly suitable for applications in extreme corrosive environments, such as marine engineering, chemical equipment, etc.

3. Thermal and electrical conductivity: TA1 titanium alloy has a low thermal conductivity of 15.24W/m · K, which enables it to maintain good performance stability in high temperature environments. Meanwhile, its conductivity is relatively low, making it suitable for use in situations that require electrical insulation.

C、 Supply Status Analysis of TA1 Titanium Alloy

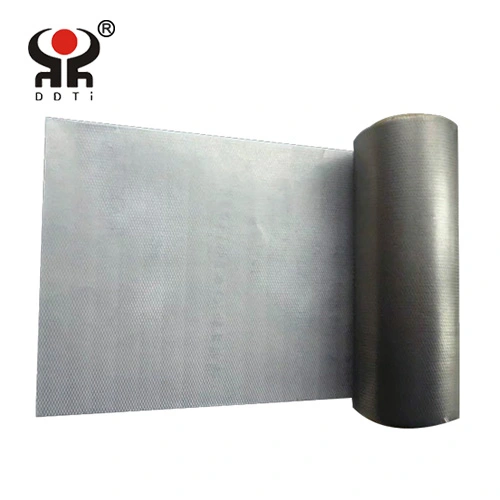

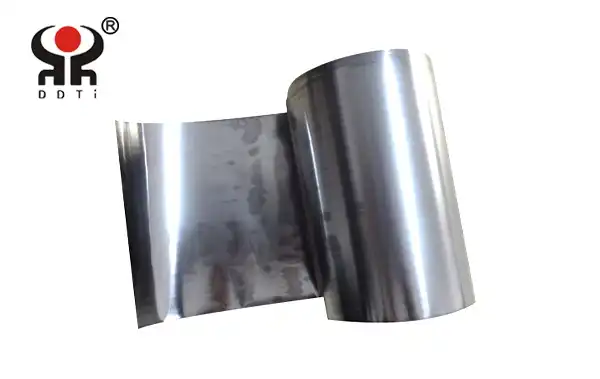

TA1 titanium alloy is usually supplied in various forms to meet the needs of different industries and application scenarios. Mainly includes: 1 Plate: The thickness range of TA1 titanium plate is usually between 0.5mm-10mm, with high flatness and excellent surface quality. These boards have wide applications in fields such as chemical equipment manufacturing and aerospace structural components. 2. Bars and forgings: The diameter of bars is generally between 5mm and 100mm, suitable for various mechanical processing and component manufacturing. Forged parts are used for processing high-strength components, such as aerospace structural parts, engine components, etc. These products undergo strict forging and heat treatment processes, possessing excellent mechanical properties and reliability.

3. Tube: The wall thickness of TA1 titanium tube is generally 1mm-10mm, and the length can reach over 6m. These pipes have a wide range of applications in fields such as marine engineering and chemical equipment pipelines, and can meet the requirements of harsh environments such as high temperature, high pressure, and corrosion.

D、 Market supply trend

In recent years, with the increasing global demand for high-performance materials, the market supply of TA1 titanium alloy has gradually expanded. As an important production base for global titanium materials, China has significantly improved the production and quality of its TA1 titanium alloy. Compared to the European and American markets, the price of TA1 titanium alloy in China is competitive, which allows more companies to choose this high-quality material to improve product quality and performance. However, the production difficulty and complex processing technology of TA1 titanium alloy limit its rapid growth in output. Therefore, in the future, TA1 titanium alloy production enterprises need to continuously strive in technological innovation, cost control, and other aspects to meet the growing demand in the market.

E、 Summary and Prospect

Enterprises can gain an advantage in the fierce market competition by gaining a deep understanding of the performance and supply status of TA1 titanium alloy, selecting suitable materials to improve product quality and performance.

Baoji Dingding Titanium Products Co., Ltd. is committed to the production of high-quality titanium materials.